Polyester Enameled Copper Clad Aluminium Wire Class155

| Nooca Alaabta | PEW/155 |

| Sharaxaada Guud | 155 Fasalka Polyester-ka La Bedelay |

| Tilmaamaha IEC | IEC60317-3 |

| Tuska heerkulka (°C) | 155 |

| Lahaanshaha | Aan la alxan karin |

| Tilmaamaha NEMA | NEMA MW 5-C |

| UL-Ansixinta | HAA |

| Dhexrooryada la heli karo | 0.08mm-1.15mm |

| Jilicsan Heerkulka Burburka (°C) | 270 |

| Heerkulka shoogga kulaylka (°C) | 175 |

| Dhexroorka magaca ah (mm) | Dulqaadka maamulaha (mm) | G1 | G2 | Korontada burburka ugu yar (V) | Kordhinta ugu yar (%) | ||

| Dhumucda filimka ugu yar | Dhexroorka ugu sarreeya oo dhammaystiran (mm) | Dhumucda filimka ugu yar | Dhexroorka ugu sarreeya oo dhammaystiran (mm) | G1 | |||

| 0.1 | 0.003 | 0.005 | 0.115 | 0.009 | 0.124 | 1200 | 11 |

| 0.12 | 0.003 | 0.006 | 0.137 | 0.01 | 0.146 | 1600 | 11 |

| 0.15 | 0.003 | 0.0065 | 0.17 | 0.0115 | 0.181 | 1800 | 15 |

| 0.17 | 0.003 | 0.007 | 0.193 | 0.0125 | 0.204 | 1800 | 15 |

| 0.19 | 0.003 | 0.008 | 0.215 | 0.0135 | 0.227 | 1900 | 15 |

| 0.2 | 0.003 | 0.008 | 0.225 | 0.0135 | 0.238 | 2000 | 15 |

| 0.21 | 0.003 | 0.008 | 0.237 | 0.014 | 0.25 | 2000 | 15 |

| 0.23 | 0.003 | 0.009 | 0.257 | 0.016 | 0.271 | 2100 | 15 |

| 0.25 | 0.004 | 0.009 | 0.28 | 0.016 | 0.296 | 2300 | 15 |

| 0.27 | 0.004 | 0.009 | 0.3 | 0.0165 | 0.318 | 2300 | 15 |

| 0.28 | 0.004 | 0.009 | 0.31 | 0.0165 | 0.328 | 2400 | 15 |

| 0.3 | 0.004 | 0.01 | 0.332 | 0.0175 | 0.35 | 2400 | 16 |

| 0.32 | 0.004 | 0.01 | 0.355 | 0.0185 | 0.371 | 2400 | 16 |

| 0.33 | 0.004 | 0.01 | 0.365 | 0.019 | 0.381 | 2500 | 16 |

| 0.35 | 0.004 | 0.01 | 0.385 | 0.019 | 0.401 | 2600 | 16 |

| 0.37 | 0.004 | 0.011 | 0.407 | 0.02 | 0.425 | 2600 | 17 |

| 0.38 | 0.004 | 0.011 | 0.417 | 0.02 | 0.435 | 2700 | 17 |

| 0.4 | 0.005 | 0.0115 | 0.437 | 0.02 | 0.455 | 2800 | 17 |

| 0.45 | 0.005 | 0.0115 | 0.488 | 0.021 | 0.507 | 2800 | 17 |

| 0.5 | 0.005 | 0.0125 | 0.54 | 0.0225 | 0.559 | 3000 | 19 |

| 0.55 | 0.005 | 0.0125 | 0.59 | 0.0235 | 0.617 | 3000 | 19 |

| 0.57 | 0.005 | 0.013 | 0.61 | 0.024 | 0.637 | 3000 | 19 |

| 0.6 | 0.006 | 0.0135 | 0.642 | 0.025 | 0.669 | 3100 | 20 |

| 0.65 | 0.006 | 0.014 | 0.692 | 0.0265 | 0.723 | 3100 | 20 |

| 0.7 | 0.007 | 0.015 | 0.745 | 0.0265 | 0.775 | 3100 | 20 |

| 0.75 | 0.007 | 0.015 | 0.796 | 0.028 | 0.829 | 3100 | 20 |

| 0.8 | 0.008 | 0.015 | 0.849 | 0.03 | 0.881 | 3200 | 20 |

| 0.85 | 0.008 | 0.016 | 0.902 | 0.03 | 0.933 | 3200 | 20 |

| 0.9 | 0.009 | 0.016 | 0.954 | 0.03 | 0.985 | 3300 | 20 |

| 0.95 | 0.009 | 0.017 | 1.006 | 0.0315 | 1.037 | 3400 | 20 |

| 1 | 0.01 | 0.0175 | 1.06 | 0.0315 | 1.094 | 3500 | 20 |

| 1.05 | 0.01 | 0.0175 | 1.111 | 0.032 | 1.145 | 3500 | 20 |

| 1.1 | 0.01 | 0.0175 | 1.162 | 0.0325 | 1.196 | 3500 | 20 |

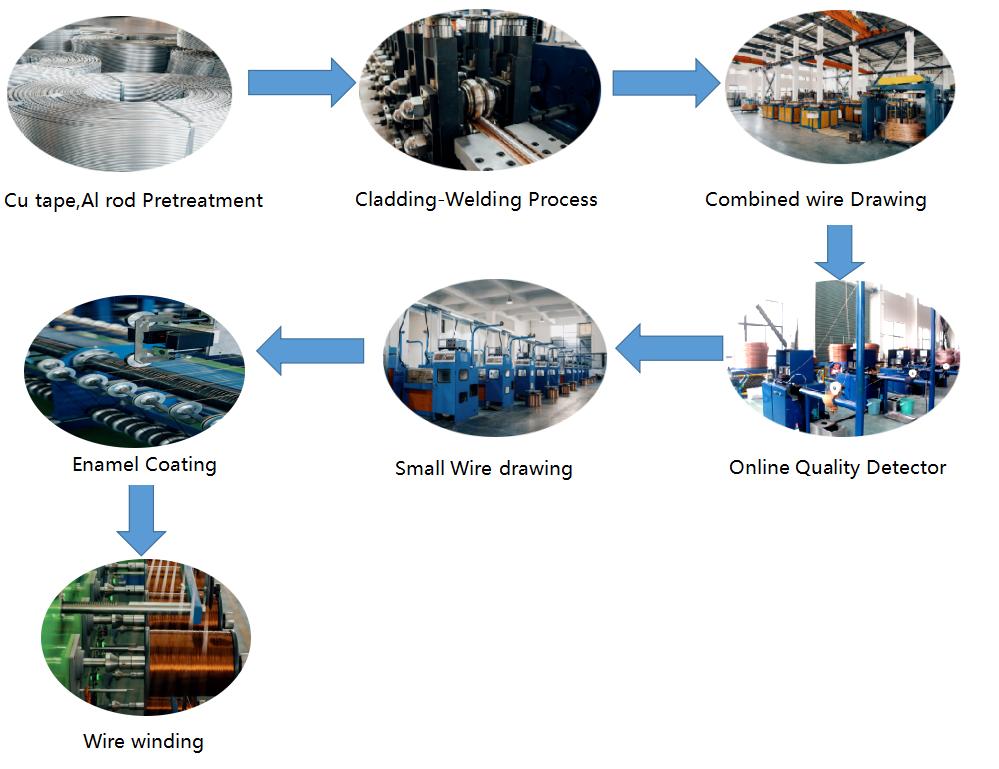

Faa'iidooyinka aluminium-ka-kooxeed ee naxaasta ah ee ka sarreeya naxaasta saafiga ah

1.Dhaqaale

Aluminium aluminium-ka-xidhan ee koodhka ah waxa lagu iibiyaa miisaan, si la mid ah kirishbooyada saafiga ah ee naxaasta ah, kuwaas oo ka qaalisan kirishbooyada saafiga ah ee isku miisaanka ah.Si kastaba ha ahaatee, korijiyeyaasha aluminium-ka-xidhka ah ee naxaasta ah ee isku miisaanka ah ayaa aad uga dheer kirishbooyada saafiga ah, fiilooyinka waxaa lagu xisaabiyaa dherer ahaan.Miisaan isku mid ah, siliga aluminium-ka-kooxeed ee naxaasta ah ayaa 2.5 jeer ka dheer siliga naxaasta ah, qiimuhuna waa dhawr boqol oo doolar oo kaliya oo ka badan tan.Marka la isku daro, aluminium naxaas ah ayaa leh faa'iido.Maaddaama fiilada aluminium ee naxaasta leh ay fududdahay, kharashka qaadista iyo rakibidda fiilada ayaa la dhimay, taas oo u keeni doonta wax ku habboon dhismaha.

2.fududeynta dayactirka

Isticmaalka aluminium-ka-xidhka naxaasta ah wuxuu yareeyaa fashilka shabakada.Sababo la xiriira kala duwanaanshiyaha weyn ee is-ballaadhinta kulaylka ee u dhexeeya kooraha gudaha ee naxaasta ah iyo aluminiumka dibadda ka ah, bilaha xagaaga kulul, aluminium kaariyada dibadda ayaa aad u fidiya kaariyada gudaha ee naxaasta ah ayaa dib u soo noqda, si aysan si buuxda ula xiriirin xiriirada dabacsan. madaxyada F;bilaha qaboobaha qaboobaha, aluminium kaariyada dibadda ayaa sii yaraanaya oo lakabka gaashaanka ayaa dhacaya.Marka fiilada coaxial ay qaadato korriinka gudaha ee aluminium-ka-xiran ee naxaasta ah, farqiga u dhexeeya is-ballaadhintiisa kuleylkiisa iyo kan aluminiumka dibadda ee aluminiumku waa yar yahay, marka heerkulku isbeddelo, fashilka soo saarista xudunta fiilada ayaa si weyn loo yareeyaa, taas oo hagaajinaysa gudbinta. tayada shabakada.

1.Transformers-ka sarreeya, beddelayaasha caadiga ah;

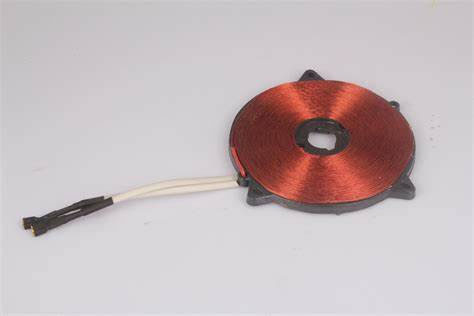

2.Inductors, gariiradaha korantada;

3.Motor, oo ay ku jiraan matoorrada guriga, mootooyinka yaryar ee kala duwan iyo matoorada leh shuruudaha sare ee deegaanka sida kombaresarada;

4.Electromagnetic fiilooyinka loogu talagalay gariiradaha maqalka, muraayadaha indhaha;

5.Electromagnetic silig for gariiradda leexsan bandhigay;

6. Fiilada korantada ee gariiradda demagnetizing;

Xulashada Bobbin

| Nooca Spool | d1 [mm] | d4 [mm] | I1 [mm] | I2 [mm] | d14 [mm] | Miisaanka dabaasha [g] | nommiisaanka siliga saafiga ah [kg] | lagu taliyay cabbirrada siligga [mm] | spools halkii sanduuq | |||||

| Silig Naxaas ah oo la dhalaaliyay | Fiilada Aluminium ee dhalaalaysa | Silig CCA ah oo la dhalaaliyay | ||||||||||||

| 10% CCA | 30% CCA | 40% CCA | 50% CCA | |||||||||||

| PT-4 | 124 | 22 | 200 | 170 | 140 | 0.23 | 6 | 2 | 2.5 | 3 | 3.2 | 3.5 | 0.04-0.19 | 4 |

| PT-10 | 160 | 22 | 230 | 200 | 180 | 0.45 | 15 | 4.5 | 5 | 6 | 6.5 | 7.5 | 0.20-0.29 | 2/4 |

| PT-15 | 180 | 22 | 230 | 200 | 200 | 0.54 | 20 | 6.5 | 7 | 8 | 8.5 | 9 | 0.30-0.62 | 1/2 |

| PT-25 | 215 | 32 | 280 | 250 | 230 | 0.75 | 28 | 10 | 11 | 13 | 14 | 15 | 0.65 ~ 4.00 | 1 |

| PT-60 | 270 | 32 | 406 | 350 | 300 | 2.05 | 80 | 24 | 24 | 28 | 32 | 35 | 0.65 ~ 4.00 | 1 |

Baakad