Polyester Enameled Copper Clad Aluminium Wire Silig Class130

| Nooca Alaabta | PEW/130 |

| Sharaxaada Guud | 130 Fasalka Polyester |

| Tilmaamaha IEC | IEC60317-3 |

| Tuska heerkulka (°C) | 130 |

| Lahaanshaha | Aan la alxan karin |

| Tilmaamaha NEMA | NEMA MW 5-C |

| UL-Ansixinta | / |

| Dhexrooryada la heli karo | 0.08mm-1.15mm |

| Jilicsan Heerkulka Burburka (°C) | 240 |

| Heerkulka shoogga kulaylka (°C) | 155 |

| Dhexroorka magaca ah (mm) | Dulqaadka maamulaha (mm) | G1 | G2 | Korontada burburka ugu yar (V) | Kordhinta ugu yar (%) | ||

| Dhumucda filimka ugu yar | Dhexroorka ugu sarreeya oo dhammaystiran (mm) | Dhumucda filimka ugu yar | Dhexroorka ugu sarreeya oo dhammaystiran (mm) | G1 | |||

| 0.1 | 0.003 | 0.005 | 0.115 | 0.009 | 0.124 | 1200 | 11 |

| 0.12 | 0.003 | 0.006 | 0.137 | 0.01 | 0.146 | 1600 | 11 |

| 0.15 | 0.003 | 0.0065 | 0.17 | 0.0115 | 0.181 | 1800 | 15 |

| 0.17 | 0.003 | 0.007 | 0.193 | 0.0125 | 0.204 | 1800 | 15 |

| 0.19 | 0.003 | 0.008 | 0.215 | 0.0135 | 0.227 | 1900 | 15 |

| 0.2 | 0.003 | 0.008 | 0.225 | 0.0135 | 0.238 | 2000 | 15 |

| 0.21 | 0.003 | 0.008 | 0.237 | 0.014 | 0.25 | 2000 | 15 |

| 0.23 | 0.003 | 0.009 | 0.257 | 0.016 | 0.271 | 2100 | 15 |

| 0.25 | 0.004 | 0.009 | 0.28 | 0.016 | 0.296 | 2300 | 15 |

| 0.27 | 0.004 | 0.009 | 0.3 | 0.0165 | 0.318 | 2300 | 15 |

| 0.28 | 0.004 | 0.009 | 0.31 | 0.0165 | 0.328 | 2400 | 15 |

| 0.3 | 0.004 | 0.01 | 0.332 | 0.0175 | 0.35 | 2400 | 16 |

| 0.32 | 0.004 | 0.01 | 0.355 | 0.0185 | 0.371 | 2400 | 16 |

| 0.33 | 0.004 | 0.01 | 0.365 | 0.019 | 0.381 | 2500 | 16 |

| 0.35 | 0.004 | 0.01 | 0.385 | 0.019 | 0.401 | 2600 | 16 |

| 0.37 | 0.004 | 0.011 | 0.407 | 0.02 | 0.425 | 2600 | 17 |

| 0.38 | 0.004 | 0.011 | 0.417 | 0.02 | 0.435 | 2700 | 17 |

| 0.4 | 0.005 | 0.0115 | 0.437 | 0.02 | 0.455 | 2800 | 17 |

| 0.45 | 0.005 | 0.0115 | 0.488 | 0.021 | 0.507 | 2800 | 17 |

| 0.5 | 0.005 | 0.0125 | 0.54 | 0.0225 | 0.559 | 3000 | 19 |

| 0.55 | 0.005 | 0.0125 | 0.59 | 0.0235 | 0.617 | 3000 | 19 |

| 0.57 | 0.005 | 0.013 | 0.61 | 0.024 | 0.637 | 3000 | 19 |

| 0.6 | 0.006 | 0.0135 | 0.642 | 0.025 | 0.669 | 3100 | 20 |

| 0.65 | 0.006 | 0.014 | 0.692 | 0.0265 | 0.723 | 3100 | 20 |

| 0.7 | 0.007 | 0.015 | 0.745 | 0.0265 | 0.775 | 3100 | 20 |

| 0.75 | 0.007 | 0.015 | 0.796 | 0.028 | 0.829 | 3100 | 20 |

| 0.8 | 0.008 | 0.015 | 0.849 | 0.03 | 0.881 | 3200 | 20 |

| 0.85 | 0.008 | 0.016 | 0.902 | 0.03 | 0.933 | 3200 | 20 |

| 0.9 | 0.009 | 0.016 | 0.954 | 0.03 | 0.985 | 3300 | 20 |

| 0.95 | 0.009 | 0.017 | 1.006 | 0.0315 | 1.037 | 3400 | 20 |

| 1 | 0.01 | 0.0175 | 1.06 | 0.0315 | 1.094 | 3500 | 20 |

| 1.05 | 0.01 | 0.0175 | 1.111 | 0.032 | 1.145 | 3500 | 20 |

| 1.1 | 0.01 | 0.0175 | 1.162 | 0.0325 | 1.196 | 3500 | 20 |

1. iska caabin DC

Iska caabbinta DC ee siliga CCA waa ku dhawaad 1.45 jeer ka siliga naxaasta ah;oo leh iska caabin isku mid ah, siliga CCA wuxuu ku saabsan yahay 1/2 culus ee silig naxaas ah.

2. Alxan wanaagsan

Siliga CCA waxa lagu dahaadhay lakabka naxaasta ah ee xooga leh, sidaa awgeed waxa uu leeyahay alxan la mid ah kan siliga naxaasta oo aan u baahnayn daaweyn gaar ah sida siligga aluminiumka;

3. Miisaan fudud

Cufnaanta siliga CCA waa 1/3 ee silig naxaas ah oo dhexroor isku mid ah;aad waxtar u leh si loo yareeyo miisaanka fiilooyinka iyo gariiradaha.

| Nooca Alaabta | Sharaxaada Guud | Astaamaha |

| PEW/130 | 130 Fasalka Polyester-ka | Iska caabbinta kulaylka wanaagsan iyo xoogga farsamada. |

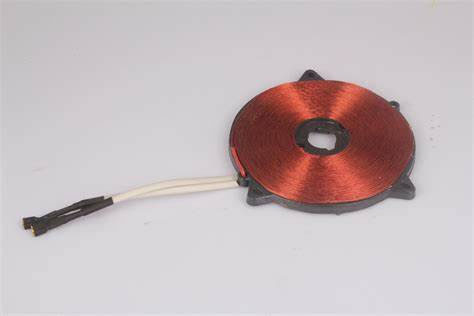

1. Sameecada codka gariiradda.Inta jeer ee ay gaari kartaa 500Hz-1600Hz, Waxay yarayn kartaa miisaanka gariir iyo ilaalinta aaminnimo sare.

2.La soco gariiradda leexashada.Waxay hoos u dhigi kartaa heerkulka gariiradda, hagaajin kartaa xasilloonida sawirka, kordhin kartaa nolosha isticmaalka.

3.Monitor degussing gariiradda.Waxay hoos u dhigi kartaa qiimaha alaabta.

4.Matoorka caadiga ah, transformer dhexdhexaad ah.

Xulashada Bobbin

| Nooca Spool | d1 [mm] | d4 [mm] | I1 [mm] | I2 [mm] | d14 [mm] | Miisaanka dabaasha [g] | nommiisaanka siliga saafiga ah [kg] | lagu taliyay cabbirrada siligga [mm] | spools halkii sanduuq | |||||

| Silig Naxaas ah oo la dhalaaliyay | Fiilada Aluminium ee dhalaalaysa | Silig CCA ah oo la dhalaaliyay | ||||||||||||

| 10% CCA | 30% CCA | 40% CCA | 50% CCA | |||||||||||

| PT-4 | 124 | 22 | 200 | 170 | 140 | 0.23 | 6 | 2 | 2.5 | 3 | 3.2 | 3.5 | 0.04-0.19 | 4 |

| PT-10 | 160 | 22 | 230 | 200 | 180 | 0.45 | 15 | 4.5 | 5 | 6 | 6.5 | 7.5 | 0.20-0.29 | 2/4 |

| PT-15 | 180 | 22 | 230 | 200 | 200 | 0.54 | 20 | 6.5 | 7 | 8 | 8.5 | 9 | 0.30-0.62 | 1/2 |

| PT-25 | 215 | 32 | 280 | 250 | 230 | 0.75 | 28 | 10 | 11 | 13 | 14 | 15 | 0.65 ~ 4.00 | 1 |

| PT-60 | 270 | 32 | 406 | 350 | 300 | 2.05 | 80 | 24 | 24 | 28 | 32 | 35 | 0.65 ~ 4.00 | 1 |

Baakad